Kunshan Royli Precision Tools Corporation LTD.

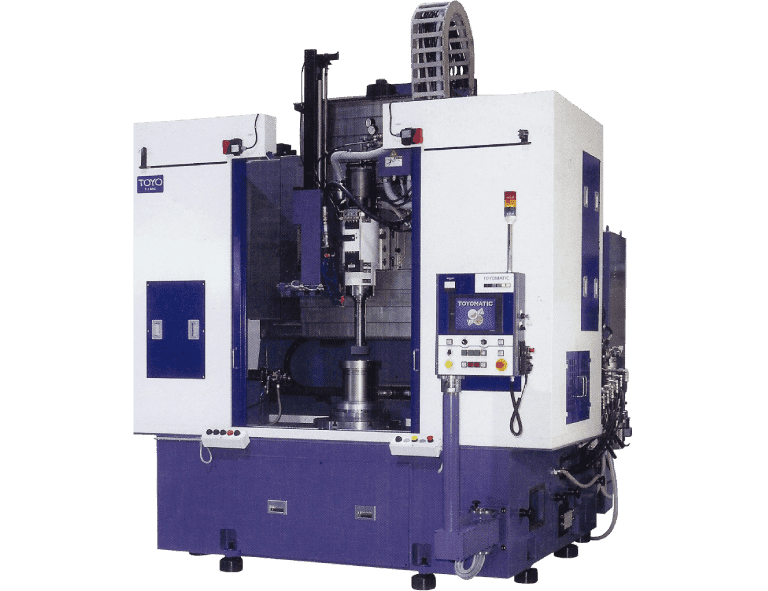

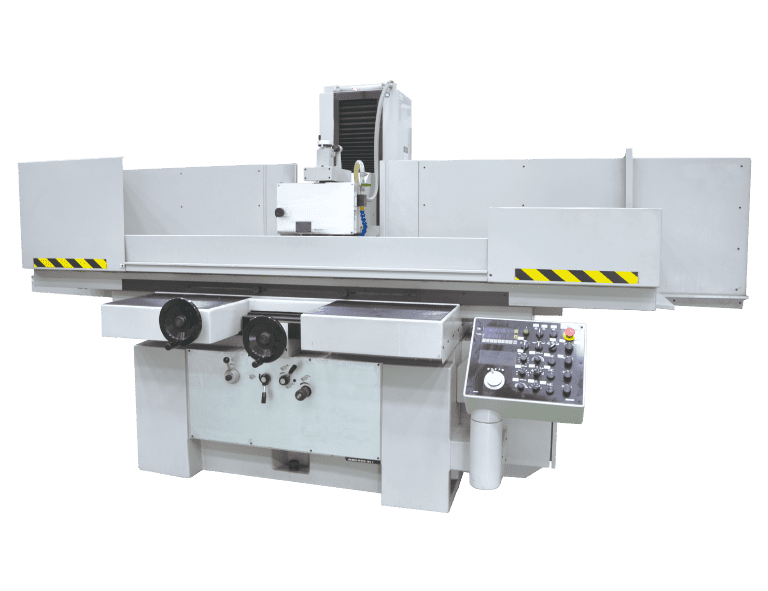

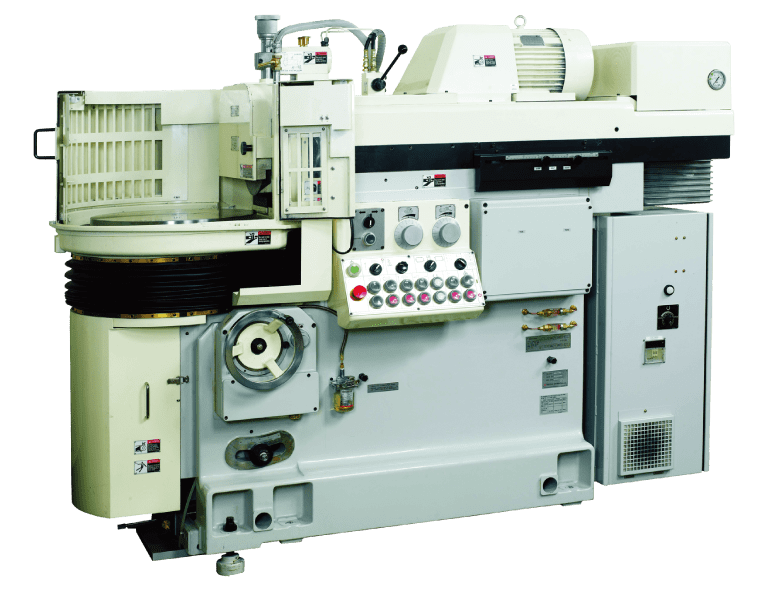

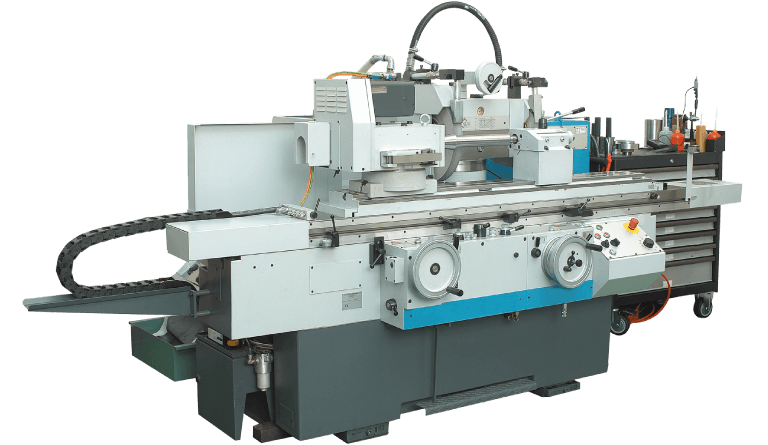

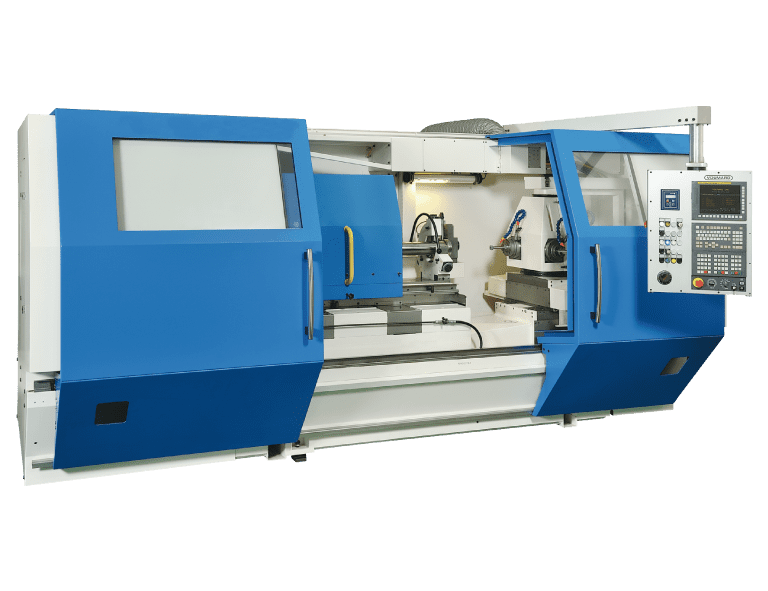

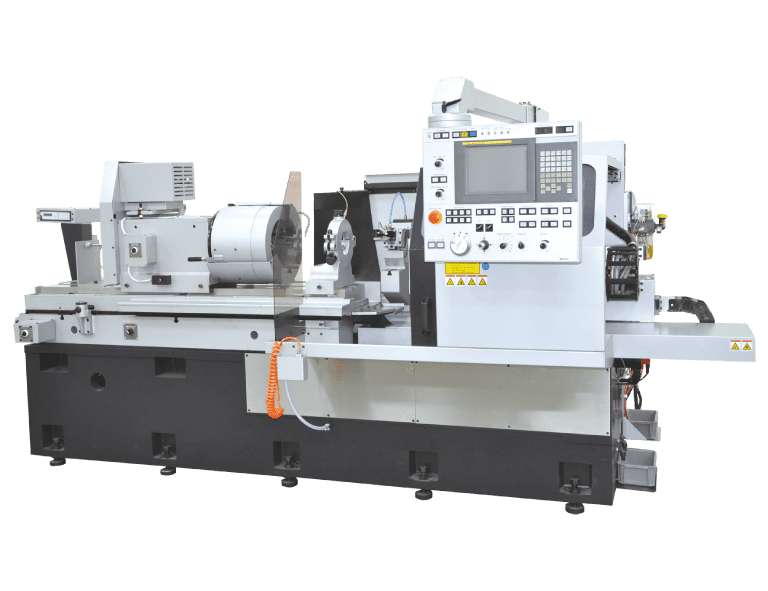

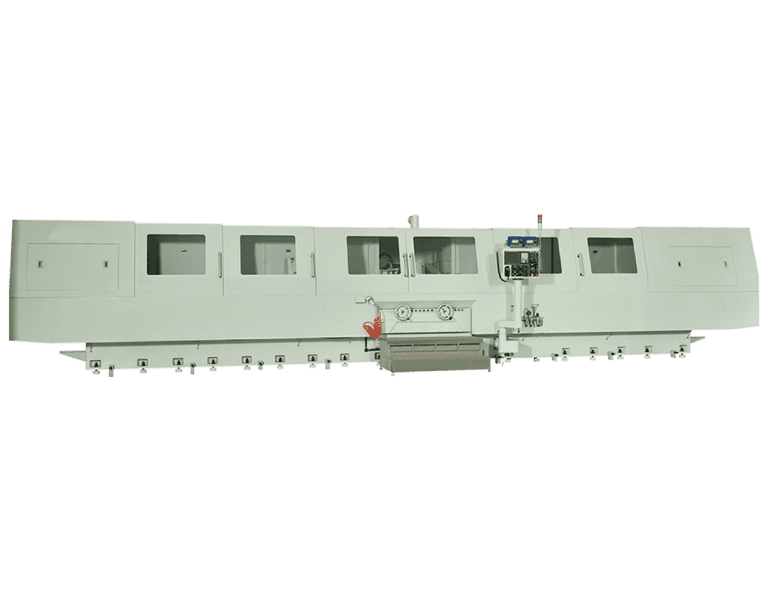

Equipments

Professional assembly technology

Constant temperature and humidity processing plant / constant temperature and humidity positive pressure clean assembly room, with smooth production process to ensure spindle quality

Spindle temperature test run

Spindle vibration, spectrum and noise measurement

Spindle static axis, radial rigidity detection

Spindle tension and accuracy detection

Strict inspection and screening, and balance and correct the rotating parts in advance to ensure the quality of the spindle after assembly

Increase the rate of self-made parts, fully mastering the key processes and vertical integration of spindle production, increasing production capacity, high-quality and low-cost parts suppliers

Professional talents and assembly process control