Kunshan Royli Precision Tools Corporation LTD.

Research & Development

R&D work project

STEP01

Specification requirements discussion

STEP02

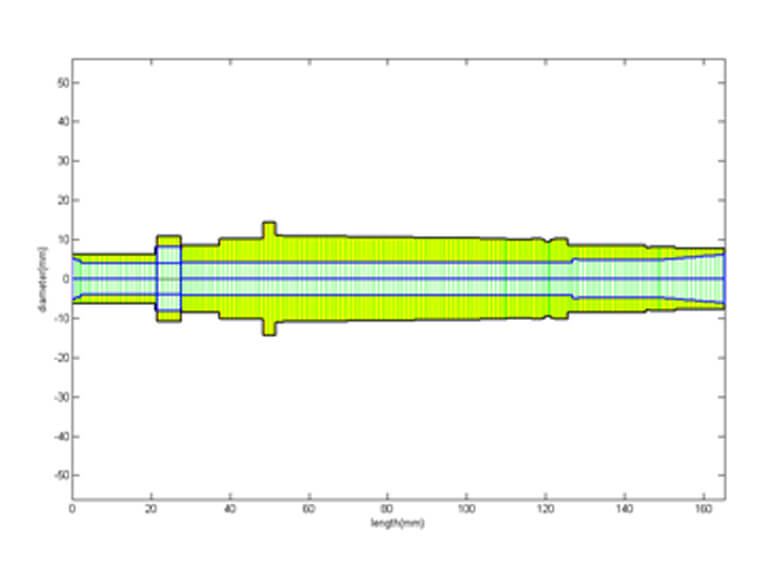

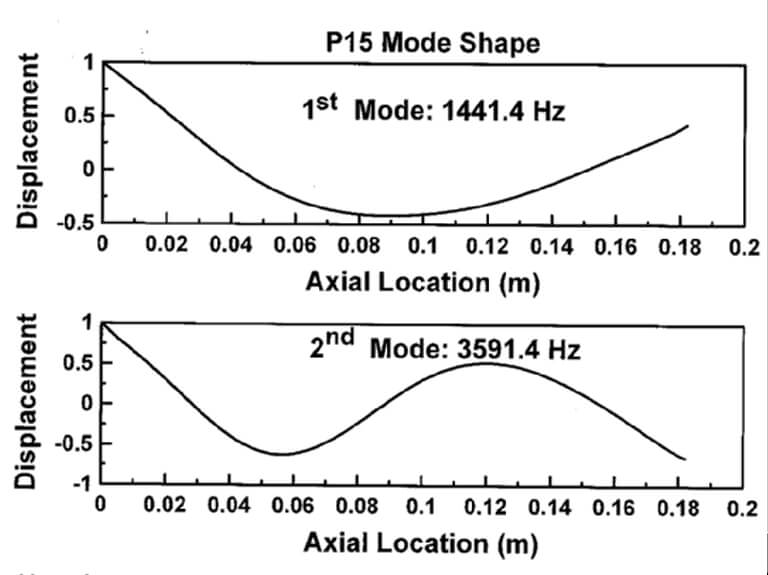

Spindle design analysis

Spindle design analysis

Motor design analysis

Stress-strain analysis

STEP03

Parts outsourcing

STEP04

Laboratory assembly test

Dynamic / static rigidity test

Motor drive test

Bearing running-in test

Shrapnel system durability test

Spindle temperature rise test

Shrapnel preload test

Spindle wear endurance test

STEP05

Product development completed

Setting of testing specifications

Standardization of assembly work

Instruction manual creation

Product DM establishment

STEP06

Trial production

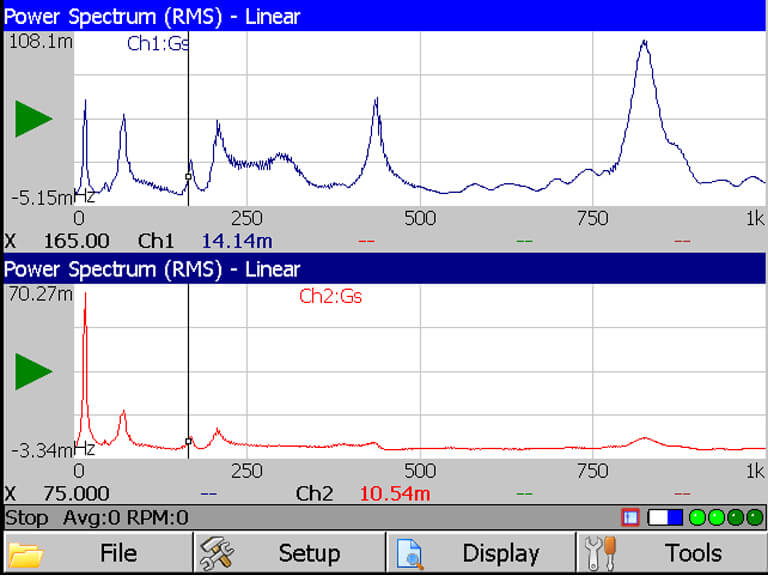

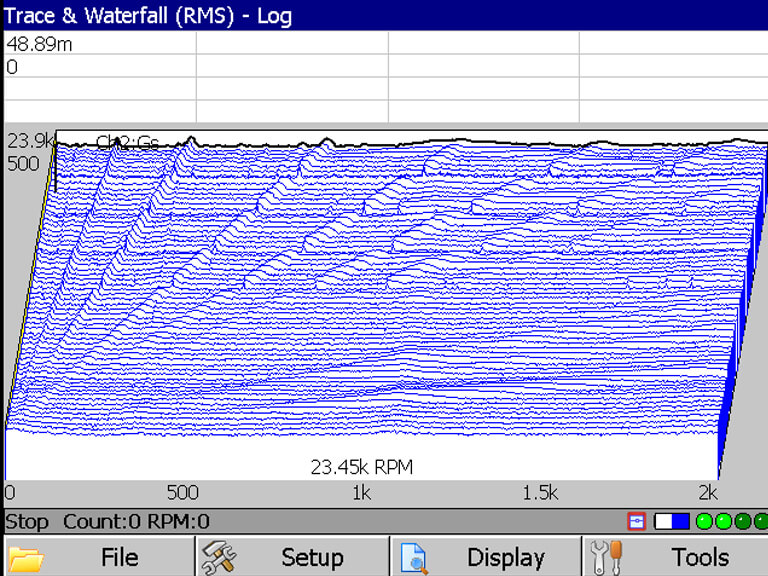

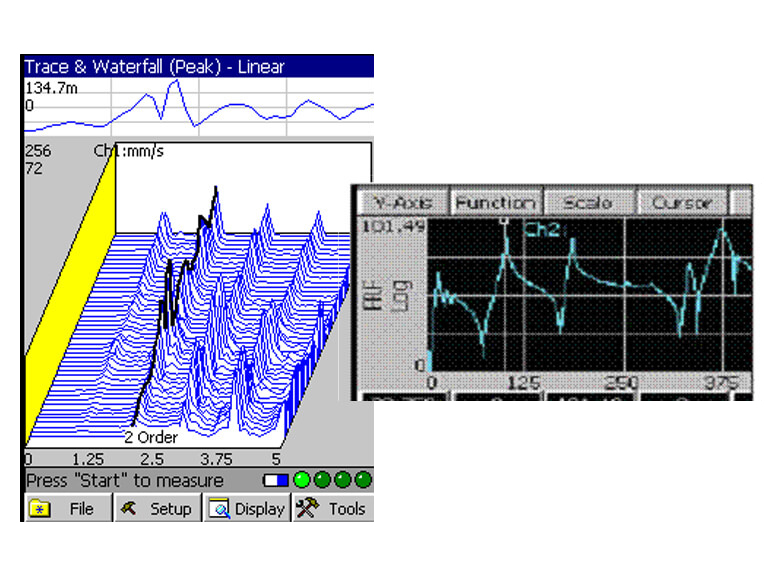

Spectrum detection

Temperature rise detection

Axial and radial static / dynamic stiffness detection

Online dynamic balance correction

Dynamic rotation accuracy detection

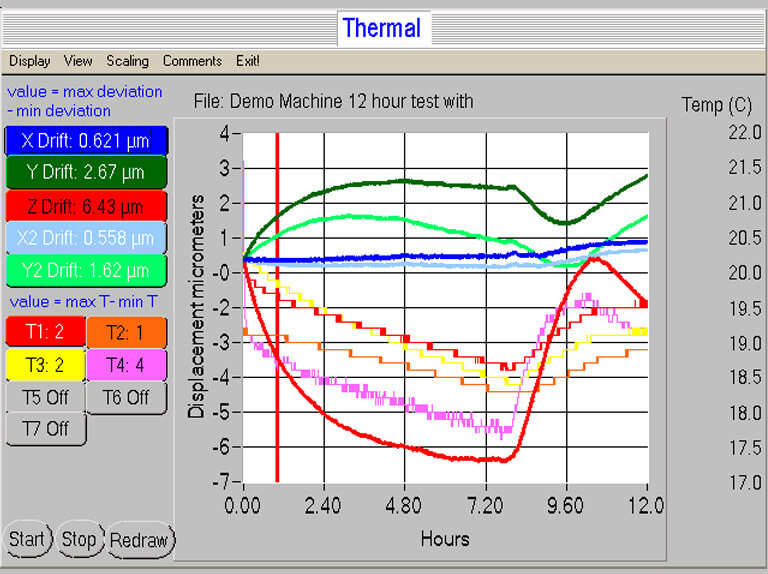

Thermal displacement detection

Ensure the reliability of high-speed spindles

Rotor-bearing system analysis

Perform spectrum detection and analysis on the running spindle to improve the quality of abnormal points.

Example: If the frequency is too high, there is a problem with the dynamic balance of the spindle.