Product List

Right T Horizontal Machining Center

Right T Horizontal Machining Center

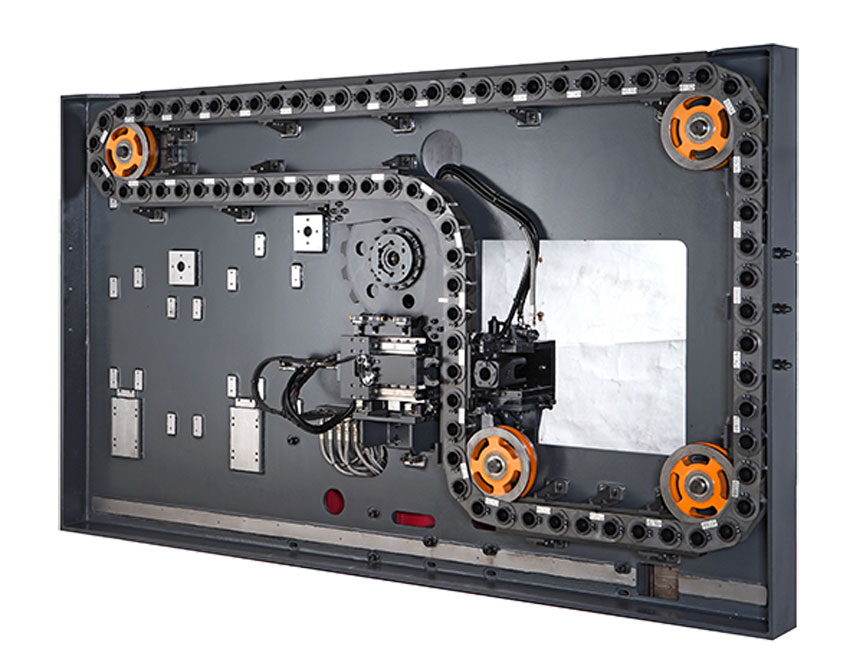

High Speed Expandable Chain Type(HCA)

Features

- The high hardness and rigidity chain, chain plate, and tool pot are through nitrogen and heat treatment, featuring outstanding reliability and long service time without tensile deformation.

- Two-step main/sub tool arm special shifting device: The tool change position is inside the magazine; sub tool arm bring tool to carrier seat, swiveling 90° to reach tool change position, saving space and shortening the tool arm length.

- Light weighted tool arm suitable for high speed tool change.

- Installed besides the machine, limited space and no interference to machining precision.

- With modularized magazine structure, it can easily be expand up to 220T by adding sub-wheel and tool pot chain.

- Magazine power source: servo / ATC power source: electric.

High Speed Expandable Chain Type (HCA) (40#-120T)

Right T Horizontal Machining Center

High Speed Expandable Chain Type

| Item | #40 |

|---|---|

| Tool Max. Dia. | Ø75 |

| Tool Max. Dia. without Adjacent Tools | Ø150 |

| Tool Max. Length | 400mm |

| Tool Max. Weight | 8kg |

| Tool Capacity | 80/120/220T |

| ATC Tool Change Time | 1.15sec/60Hz (≦8kg) |